Our Services

Our Services

Our service supports you with extensive expertise and tailored solutions from planning to implementation, ensuring your vision is realized with precision, efficiency, and personal commitment.

Tailored Solutions

- Standardized Modules: Development of OSM solderable modules, perfectly aligned with your requirements.

- Custom Carrier Boards: Design and manufacturing of individualized boards for optimal integration.

- Flexible Customization: Hardware and software solutions precisely tailored to your application

- Series Production: Scalable manufacturing for the highest quality and efficiency.

- Software Development: From Yocto and Linux operating systems to customized applications.

- End-to-End Service: Support from the initial concept through the entire product lifecycle.

What We Offer

Step 1.

Intensive consulting is the foundation for finding the best solution for you. Our team works individually with you, understanding your requirements as our challenge. We see ourselves as your strategic partner, ensuring your success.

Consulting/Service

Step 2.

Our vision is to be a leader in the development of embedded technologies that make industrial processes more efficient and future-proof. We place great emphasis on innovation and sustainability.

Development

Step 3.

We guarantee the highest quality thanks to our in-house production. Our processes are optimized for modern SMT assembly so that we can flexibly and efficiently produce both prototypes and series production.

Production

Step 4.

Each module undergoes rigorous testing in our production facility to ensure that it meets the highest requirements. We ensure maximum reliability with comprehensive functional tests and quality assurance measures.

Test Phase

Step 5.

Precision and efficiency are at the heart of the manufacturing and assembly of your products. Using state-of-the-art technology and standardized processes, we ensure the highest quality in production, tailored to your requirements.

Assembly

Step 6.

To ensure your products are at the right place at the right time, we provide efficient and reliable logistics. Our optimized supply chains and flexible planning guarantee on-time and cost-effective delivery worldwide.

Logistics

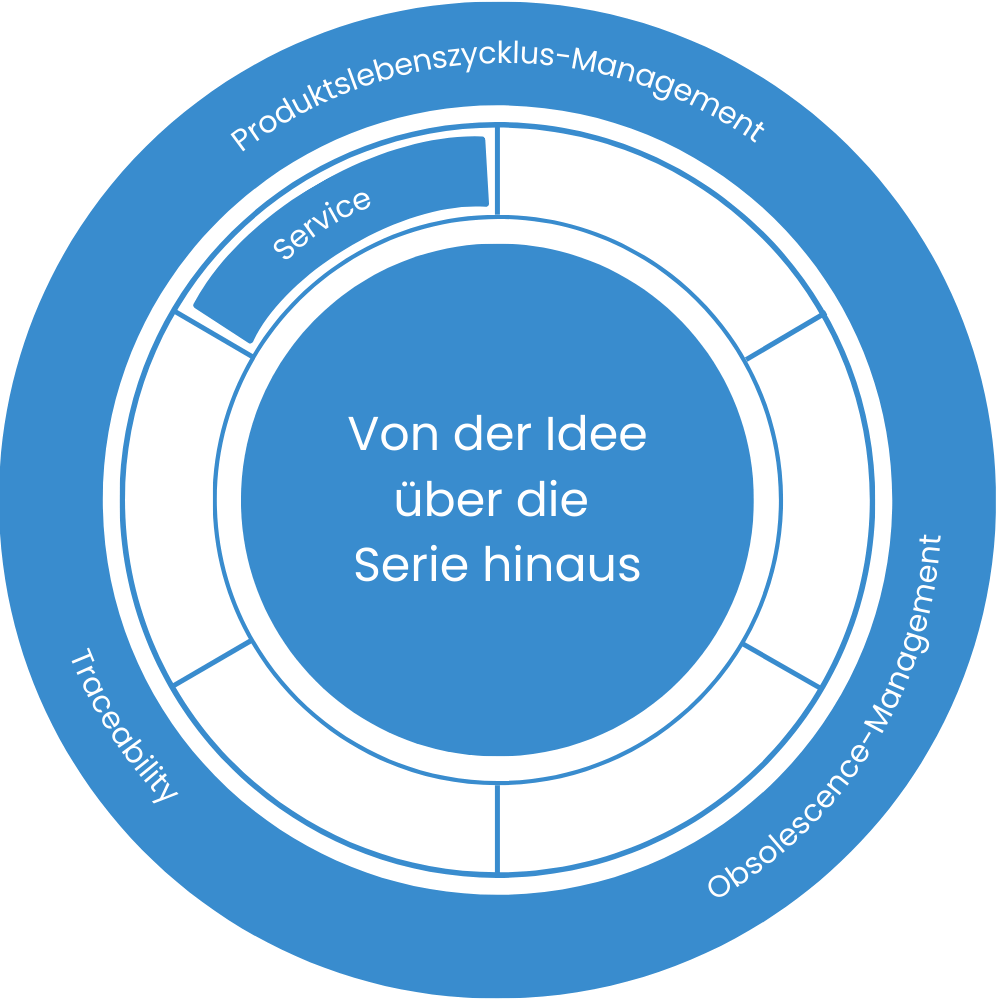

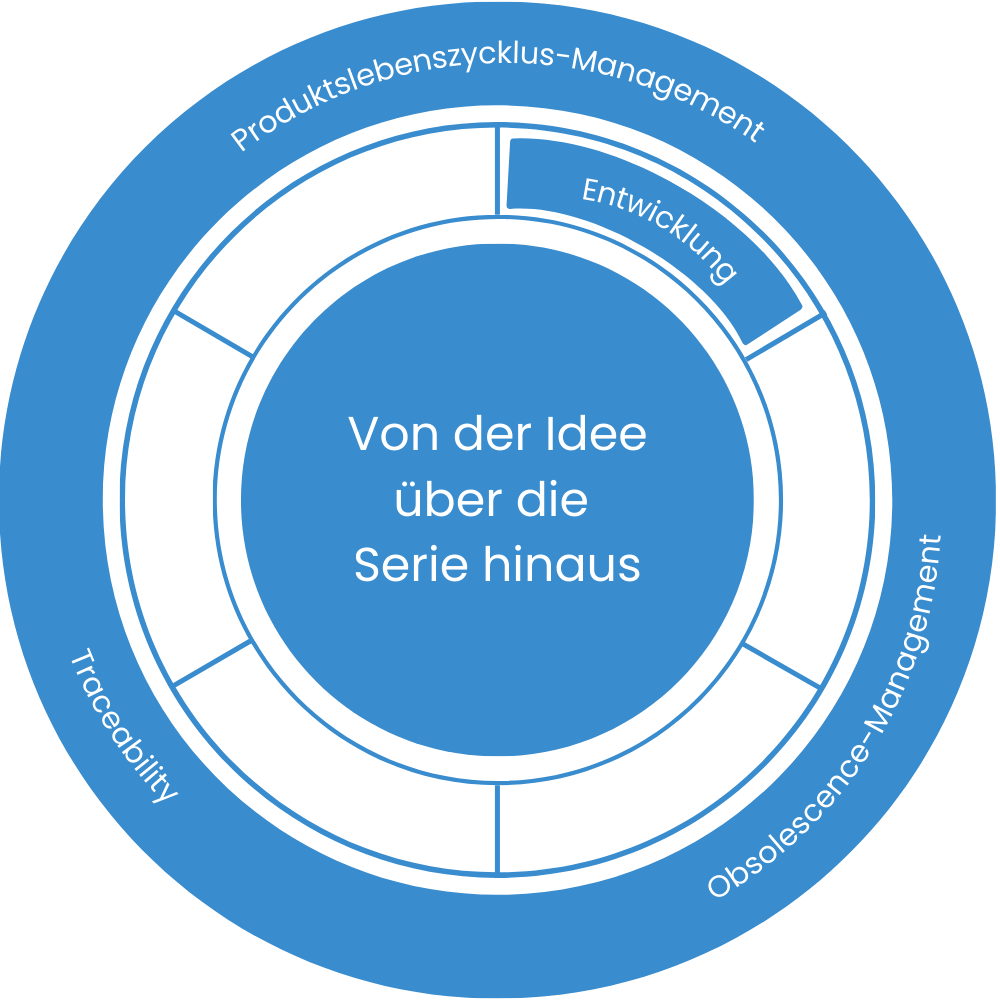

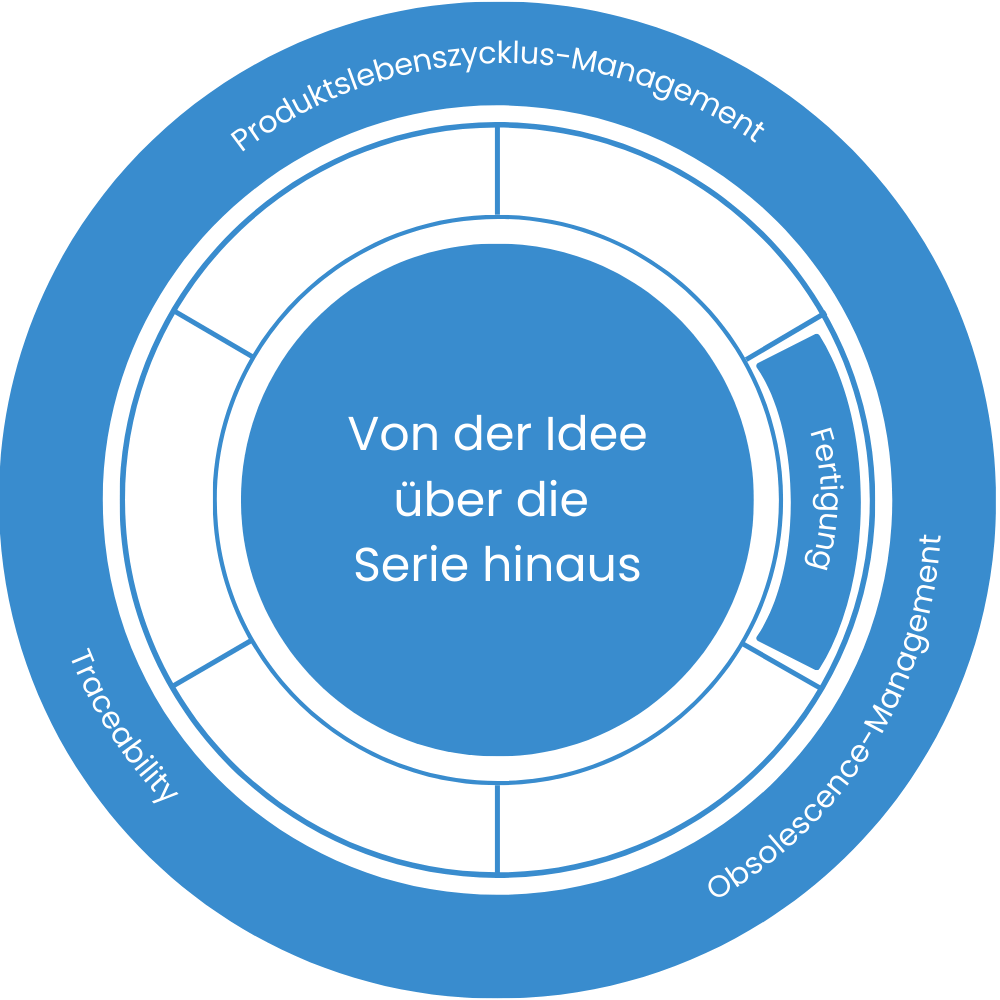

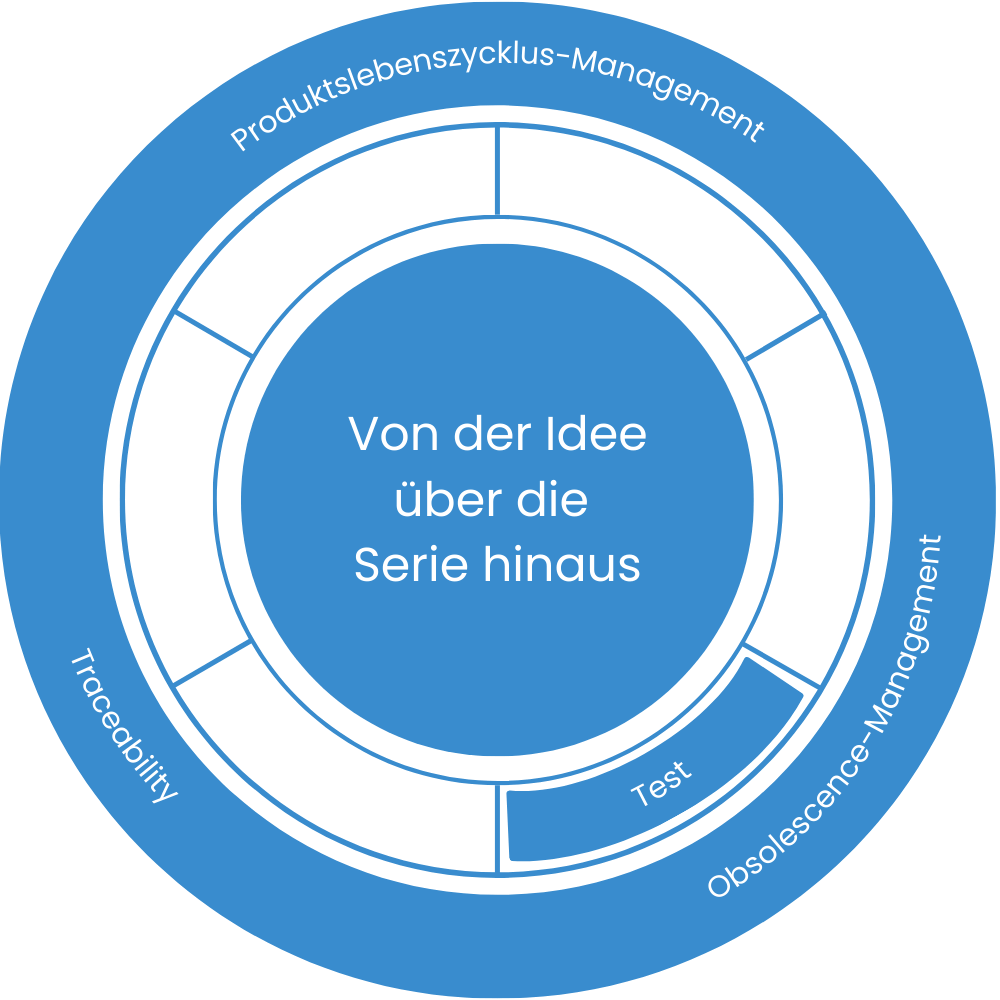

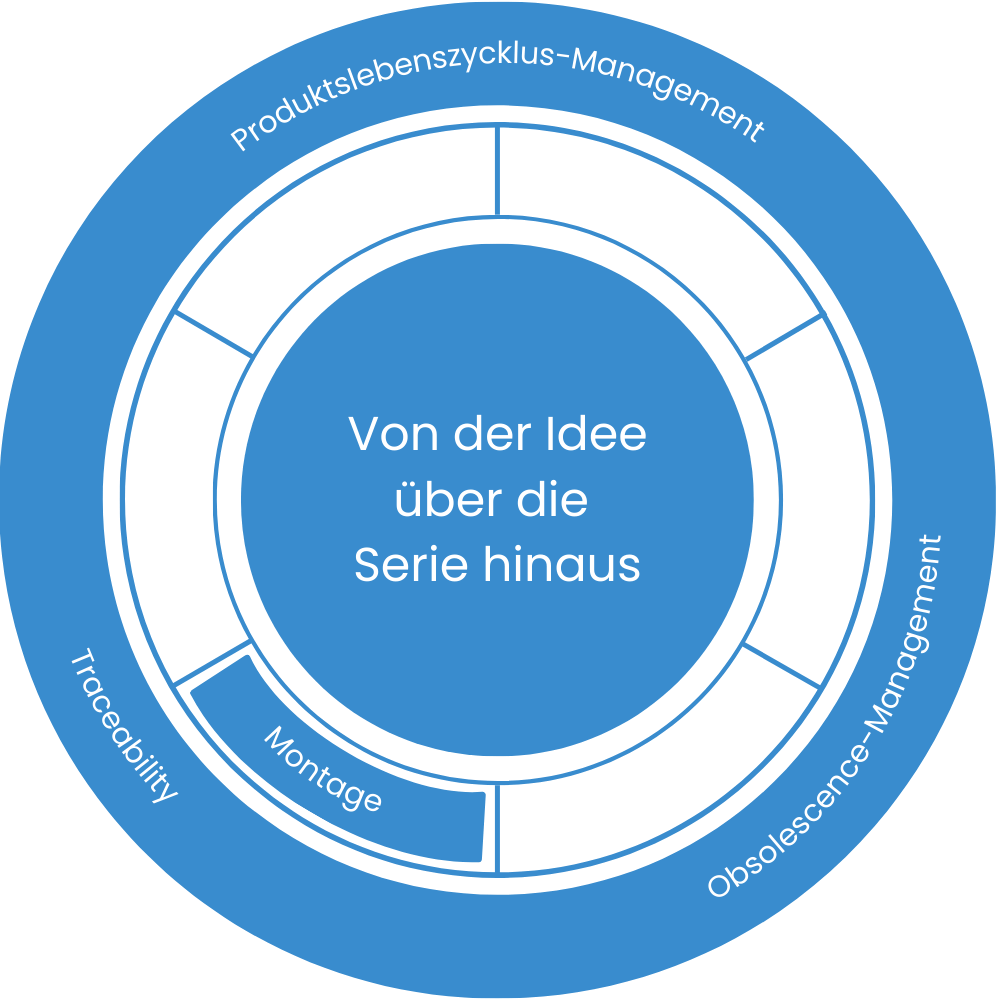

Circular Diagram: From Concept to Beyond Series Production – Service, Assembly, and Logistics

Electronic Engineering

- Computer on moduls, QSeven, eNuc boards, baseboards

- Complete systems

- Boxed-PC

- Advanced system electronics, visualization and control, electronics for field buses

- Function test systems

READ MORE

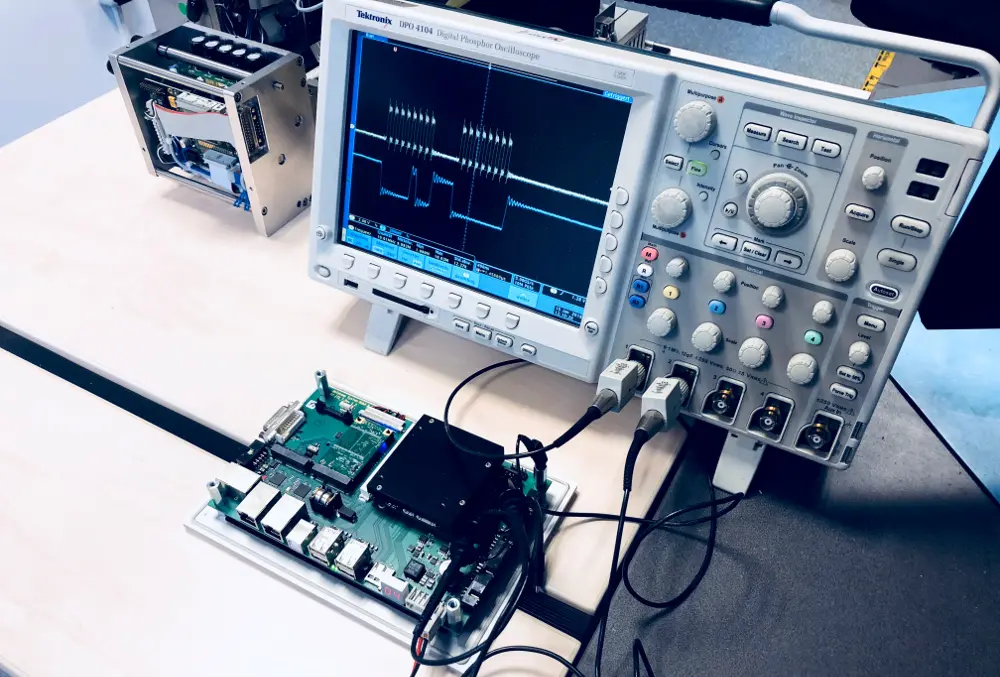

First launch of newly developed designs

In collaboration with our partners we are doing SMT assemblies for prototypes. Before the device gets powered up the first time, we check all solder connections by an initial optical inspection. Sometimes you can see simple faults like shorts on IC pins without digging any deeper.

Afterwards when everything seems ok we are powering the board up step by step. These steps could be flashing a firmware to a PMIC or microcotroller, measurung quiescent current, voltages and other significant units. In case the board is working properly until that point we are going to check the functions of the assembly by writing and executing crude test programs.

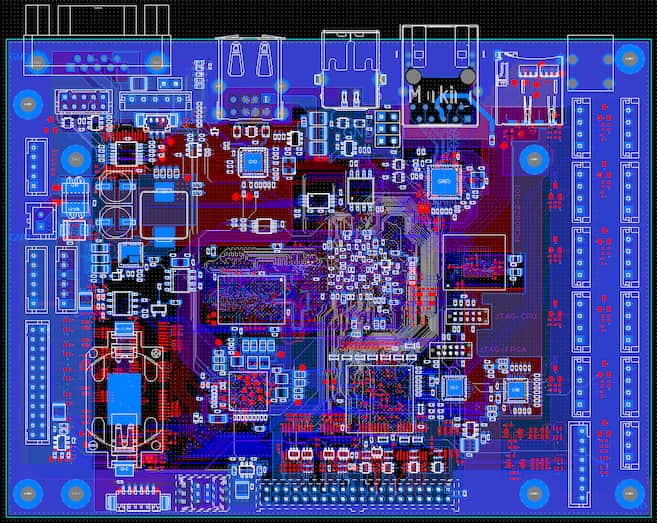

cadence® – Modern PCB layouts

cadence® is a software solution mainly consisting of schematic and pcb layout program. It is one of the most widely used solution for the creation of circuit boards.

It provides us a powerful design constraint manager to avoid failures. This means we can rout faster and benefit from advanced routing technology. Big manufacturers like AMD®, Intel® etc. work with cadence® products, in that case approved layouts with high integrity and complexity can be reused. A perfect layout is essential for a good performance and increases lifecycles.

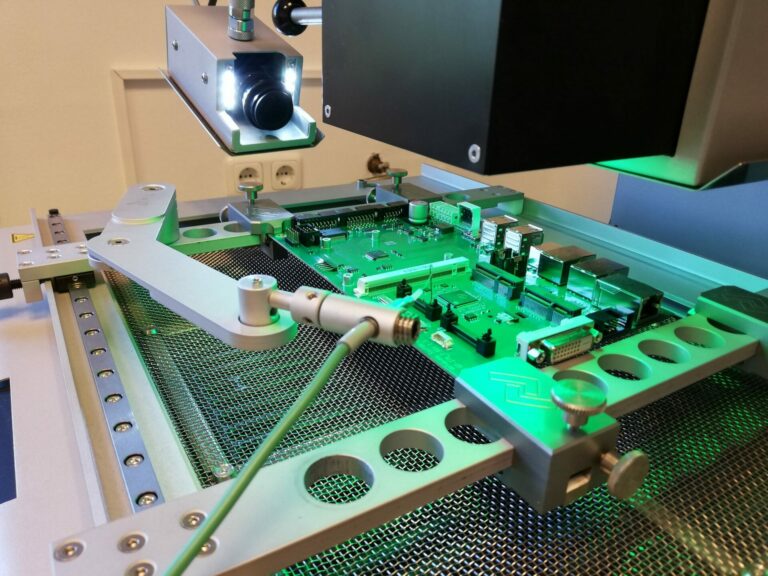

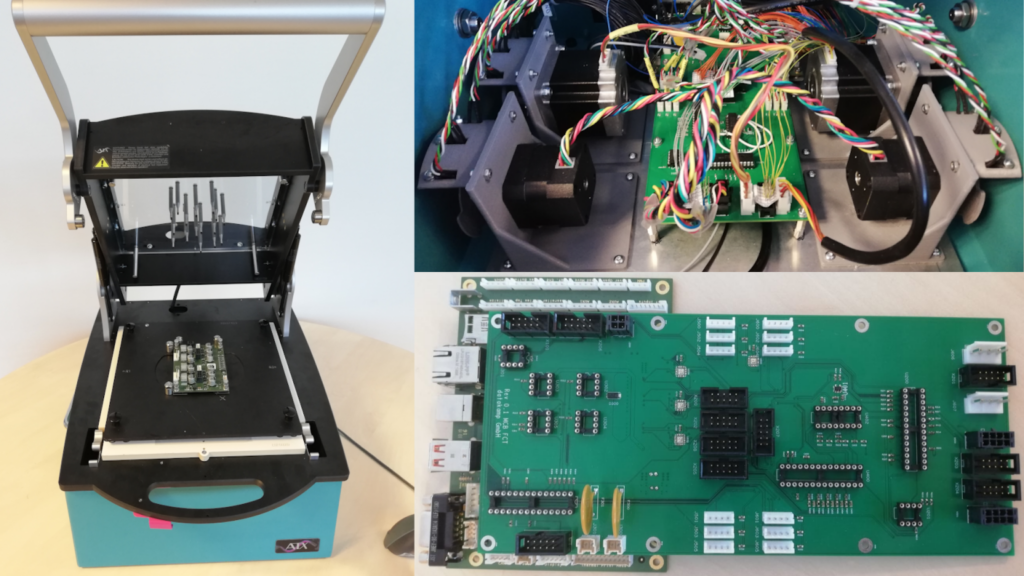

Test solutions for complete systems

The steadily shrinking structures of microelectronics also increase the complexity of an PCB assembly. In this connection, the effort of testing raises considerably. To keep the quality up, it is necessary to guarantee, that all boards are testet in equal conditions.

To meet that requirement, we are developing semi automatic testers for embedded devices. This includes the development of electronic hardware and software. The mechanic components like the housing, needle beds and wire wrap connections are second source. Small customized parts can be manufactured in our house with different kinds of additive manufactuing. Standard interfaces that need to be tested are: I2C, SPI, Ethernet, CAN, USB, GPIO and others.

When switching to semi-automatic testers, you benefit from time savings and consistent quality. In one case we were able to shorten the time for testing from two hours to two minutes.

KiCad – free software

We are going forward with eyes wide open and a part of the future will be open and free software. KiCad has a great functionality in capturing schematics and doing layouts. The only limitation are 32 copper layers and the size of RAM memory where the program runs on. It comes with a build in 3D viewer to get a quick impression on how the pcb can look like, when it is finished. The greatest benefit is the open source infrastructure. A really big library consisting of symbols and footprints are free available. That saves a lot of time. Additional you can share layouts and schematics without being worried about buying licenses.

System Development

- Construction of castings, frames, cassettes, component part carriers and foil veneers

- Creation of system- and manufacture documentations

- Develop and maintain a well-documented SDLC (System Development Life Cycle) for all system and application development processes

READ MORE

Hardware Development with Dassault Systèmes SOLIDWORKS®

SOLIDWORKS® 3D CAD is a solid modeling computer-aided-design (CAD) program. It let us shorten product development time, reduce costs and improve the quality of or products. With the big amount of functionalities we are able to validate and simulate our designs virtually. This helps to prevent from faults in the later design process. In combination with our 3D printers it is a highly effective tool to rapidly develop prototypes. To check the functionality and avoid mistakes caused by too tight tolerances it is often neccessary to build prototypes in the early design process. It also gives our clients the ability to have their hands on, while the whole process is going straight forward.

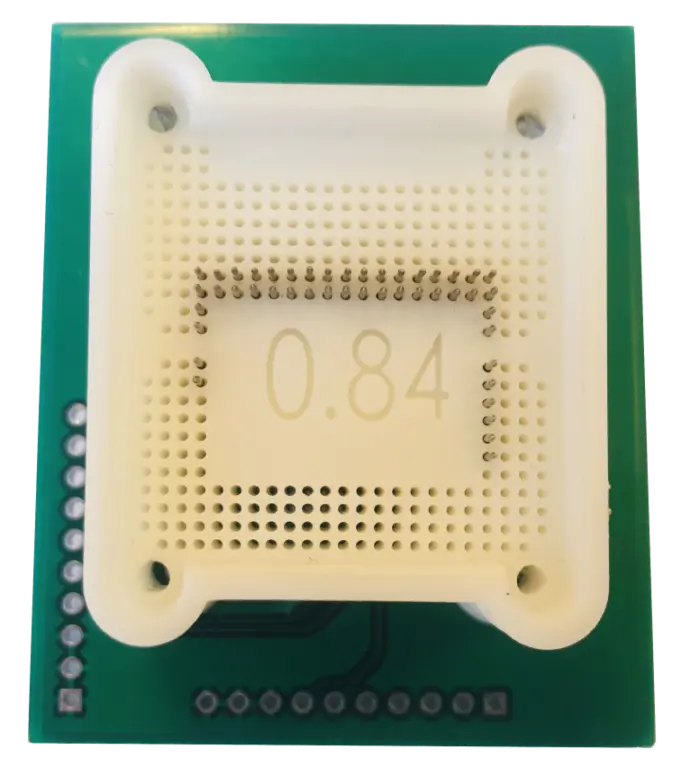

DLP Printing – Digital Light Processing

DLP 3D printing technologies make use of a (liquid) photopolymer resin that is able to cure (solidify) under a light source. These printers are equipped with a projector screen which flashes an image of a layer all at once.The precision is limited by the resolution of the projector. Each pixel takes place in a surface of 50×50µm.

With this kind of technique we are manufacturing customized parts in a quick and precise way. Especially when parts need to be more temperature stable, this can be the solution. Parts are temperature stable up to over 200°C.

To the right you can see a little mounting plate for 65mil needles. It was made to test a computer on module with outer dimensions of 30x30mm.

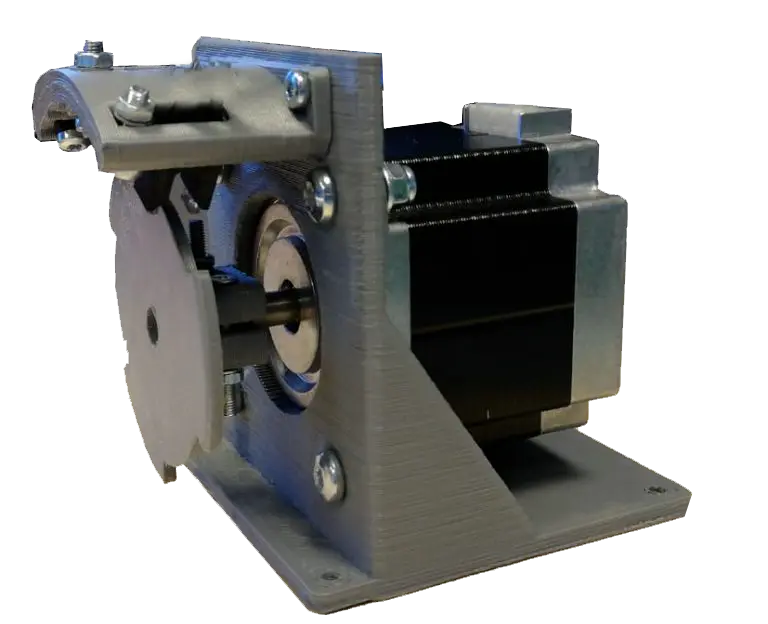

FDM Printing – Fused Deposition Modeling

FDM Printers use a process called Material Extrusion. A spool of filament provides the material supply. The filament is fed into a heated nozzle where it melts. Along specific coordinates, which are defined in a sliced 3D object file, the head of the 3D printer moves over the building plate, creating the solid.

FDM printers and the corresponding feeding materials are pretty cheap. For parts with low technical requirements this technique is a very good solution to quickly manufacture prototypes.

Here you can see customized motor mountings for a function tester. Light barriers are roughly sensing the movements of the motor.

Production

- Serial production

- Initial software launch

- Pre and final assembly

- Final test of assembly, equipment and system

- Specific climate test procedures

- CE certifications in collaboration with our partners

- Vakuum packing

- Picking, packaging and shipping

- Computer / Circuit Board Repair and Rework Services

READ MORE

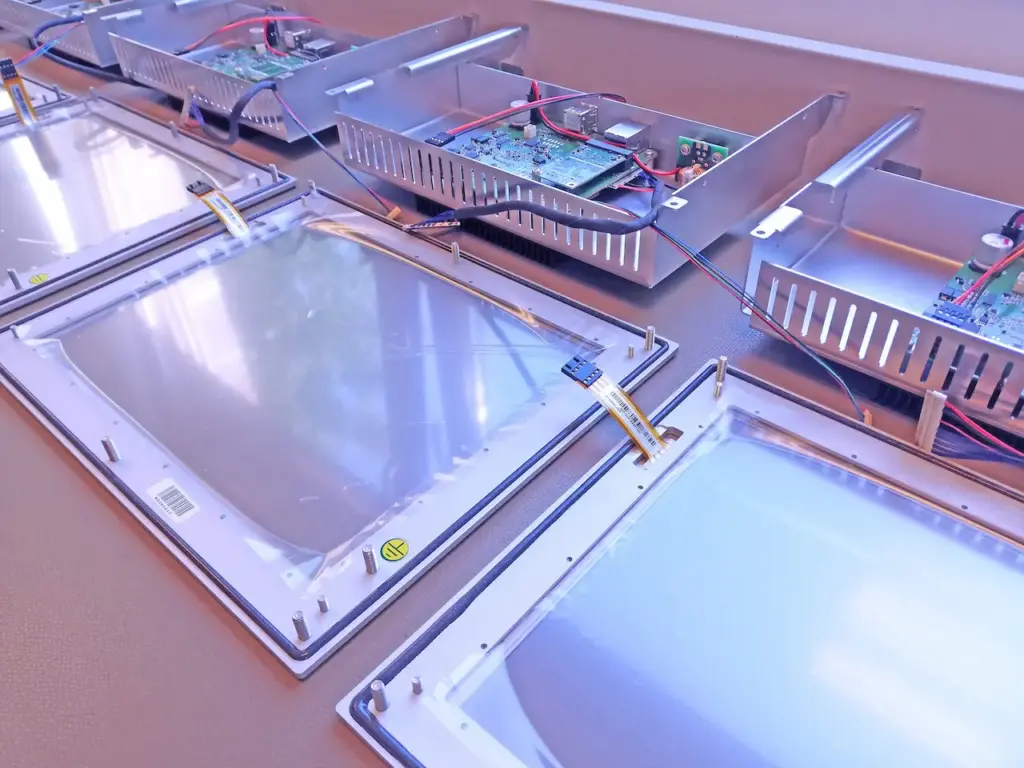

Climate Chamber – Advanced Condition Testing

We are using the Weiss WT 180 climate chamber to perform burn in tests. This testing process will force certain failures to occur under monitored conditions. In this way we research the resilience of our products.

All newly developed products have to pass our 24 hour stress test. Every 15 minutes the devices restarts, while a specific temperature curve between 0 to +65°C is followed. If a device fails to start it will be sorted out.

In general we are able to program temperature curves in a range of -40 to 180°C. So we offer our customers the service to perform burn in test für every single delivered device to fit their needs.

Reworkstation & Repair

Sometimes PCBs are faulty even after the AOI (Automated Optical Inspection) and ICT (in Circuit Test), but they fail in the FCT (Function Test). With our rework station we are able to exchange faulty ICs. It gives us the ability to precise place, solder and inspect ICs with highly integrated structures like BGAs.

The Ersa Hybrid Rework HR 550 delivers a homogenic warming of the whole assembly by applying energy from a downside up infrared heating element. It provides a 1500 W hybrid heating element to desolder and solder SMT components up to dimensions of 70 x 70 mm. To rework a target hardware the station manages customizable temperature profiles. The component that has to be reworked is applyed with a high precision vacuum device.

Embedded Computers or modules are more complex today than ever before, but despite how severely damaged they may be, they can be repaired. Indeed the high value of many embedded Computers or modules demands that they be repaired. Even less expensive assemblies maybe require repair because just-in-time manufacturing and tightly controlled production runs leave little room for shortage. Just a few years ago, such Systems were much simpler and repairs were relatively easy. Today’s they have fine pitch components, ball grid arrays and fine line circuits making them a challenge to repair. Yet, we’re driven by simple economics and must repair damaged assembly whenever possible. Whether repairing damaged internal circuitry or reworking cold solder joints. the technicalknowledge and manual skills needed for high reliability repair and rework are indeeddemanding.